Eliminate Ozone Your Corona Treater Exhaust

Did you know that ozone is a natural byproduct produced during the corona treating process? Enercon removes this ozone from the work environment through its electrode assembly exhaust.

Converters and Film Extruders install Enercon Ozone Decomposers as part of their corona treater exhaust system prior to the exhaust being released into the atmosphere.

The Ozone decomposer converts the captured ozone into oxygen before being released into the environment. Enercon ozone decomposers are designed to work with all corona treater makes and models.

How it works:

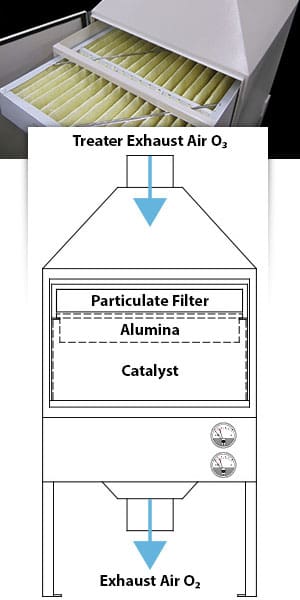

Ozone-laden air enters the unit from the top and first passes through a particle filter, which removes dust and debris to prevent contamination or blockage of the catalyst bed.

Next, the air stream flows through an additional pre-filter layer for enhanced purification before reaching the catalyst section. Within the catalyst bed, metal oxide pellets facilitate the conversion of ozone (O₃) into molecular oxygen (O₂). Provided no other harmful substances are present, the treated air can be safely discharged into the atmosphere.

To maintain safe operating conditions, ozone and other hazardous gas concentrations should be routinely monitored. Regular checks help ensure compliance with health standards and indicate when the catalyst requires reactivation.

Enercon systems are designed to operate in a maximum ambient temperature of 40°C (104°F) @ 80% relative humidity, non-condensing.

KEY FEATURES Ozone Decomposer

-

Destroys Ozone Created from the Corona Treatment Process

-

Install as part of your corona treater exhaust system