LEARN MORE All Technical Articles

High Definition Corona for Converting

How do you evaluate the performance of your corona treater? Most converters measure dyne level. That's a good start. But dyne level only measures wetting out. The real test is...

Roll Covering Options for Extrusion Film Treating

One of the most common questions asked by film extruders and converters is which roll covering is best for their application. You might be surprised at the variety of choices...

Corona Treatment: An Overview

Abstract With the advent of readily available nonpaper substrates (plastics and foils) in the mid-to-late 1950’s, the requirement for a reliable production speed surface treatment process became apparent. Several different...

Options for Surface Treating Extruded Film

Traditionally, film extrusion lines utilize a metal electrode and covered roll configuration. However, there are exceptions. Some companies choose a Bare Roll system to eliminate any roll covering concerns. Fixed or segmented...

Why All Films Do Not Treat the Same

The Signature Relationship Between Your Film and Corona Treaters How well do you understand the relationship between your films and your corona treater? A treatment level of 2.0 watt density...

Optimizing Blown Film Line Layouts For Improved Surface Treating Performance

In today’s race to produce film faster, thinner and with lower tension, reliable surface treatment is critical for success. There are a number of different philosophies employed when setting up...

Clearing the Air on Atmospheric Plasma Surface Treaters

The term "atmospheric plasma" is creating a buzz throughout the main stream converting industry. The promise of higher dyne levels, longer lasting dyne levels, superior adhesion performance, grafted surface chemistry...

Surface Treatment Comparison Chart

Which technology is best for your application? Our surface treating comparison chart can help you decide. Find out how corona, atmospheric plasma, and flame compare and learn about the application...

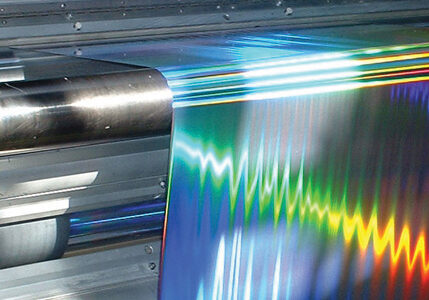

Corona Treating Basics

Corona treating increases the surface energy of plastic films, foils, paper and polymer objects to improve wettability and adhesion of inks, coatings and adhesives. Treating works best when a substrate...