Applications for Plasma Treatment of Objects

Treatment of polymer objects promotes adhesion for printing, painting, coating, bonding and labeling.

Printing

Surface treating parts prior to printing enhances ink adhesion. It makes printing easier, and for others it makes printing possible.

Painting

Injection molded or thermoformed parts are often treated prior to painting. Surface treatment allows the paint to adhere and also increases the life and durability of the paint on the object’s surface.

Coating

Products are coated to protect their surfaces from harsh environments or as decoration. Doors, frames, and extrusions/profiles are often coated. The medical industry uses surface treating to improve adhesion of antimicrobial/antibiotic coatings.

Bonding

Bonding is primarily used to increase the strength of an adhesive. The medical and automotive industries rely on surface treating to remove contaminants such as dust, grease, oils, or mold to improve bonding. Typical cleaning solvents such as methyl ethyl ketone (MEK), trichloroethylene, toluene, or acetone may be used for this purpose, but cleaning agents that leave a film residue upon evaporation will retard bonding.

Labeling

Surface treating caps, bottles and lids ensure that labels will not peel off before complete destruction of the label occurs. Air, flame and chemical plasma treatment of materials like HMWHDPE can effectively improve adhesion of labels.

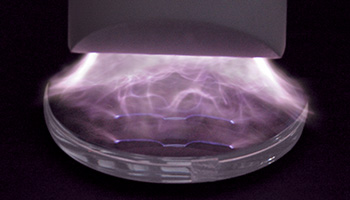

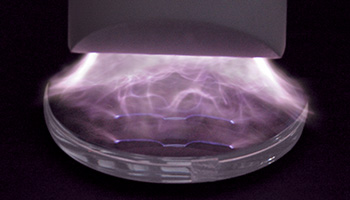

| Air Plasma Application Gallery | ||||

|---|---|---|---|---|

| Medical | Electronics | Packaging | Wire & Cable | Optics |

|  |  |  |  |

| Syringes Catheters Tubing | Cell Phones Appliances PDAs | Lids/Caps Bottles Cups | Tubes Pipes Moldings | Lenses Fiber Optics Mirrors |

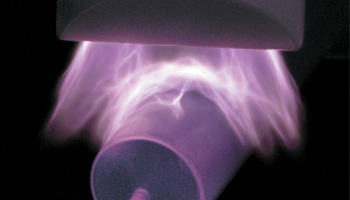

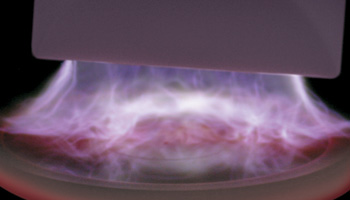

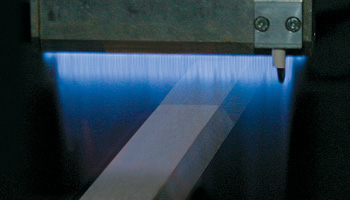

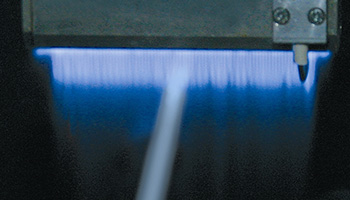

| Flame Plasma Application Gallery | ||||

|---|---|---|---|---|

| Packaging | Construction | Automotive | Decorating | Industrial |

|  |  |  |  |

| Containers Bottles Lids | Flooring Windows Doors & Cabinets | Engine Components Body, Trim & Bumpers Lamp Assemblies | Buckets Cups Caps | Tubes Pipes Mouldings |