Corona Treaters for Printing, Coating & Laminating

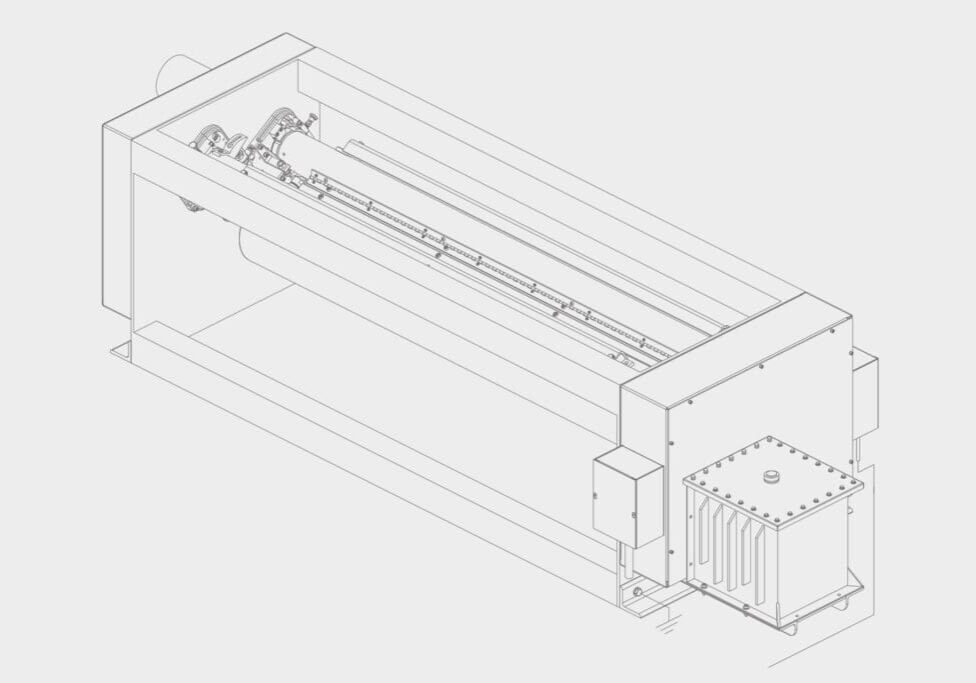

Printers, coaters and laminators rely on Enercon for high powered corona treaters to improve the adhesion of inks, coatings and laminations. Our engineering team custom designs corona treaters to meet your application requirements and seamlessly integrate with your OEM equipment.

Our local engineers in India work with the global resources of Enercon to ensure your corona treater is optimized for your application. Based on your line speeds and film type we’ll recommend idler rolls, nip rolls and integrated drives to ensure proper corona treatment.

The most popular design for converting applications features Enercon’s high powered ceramic electrodes and ground rolls capable of treating conductive and nonconductive films.

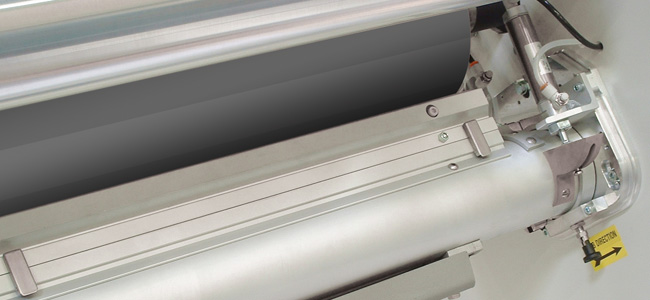

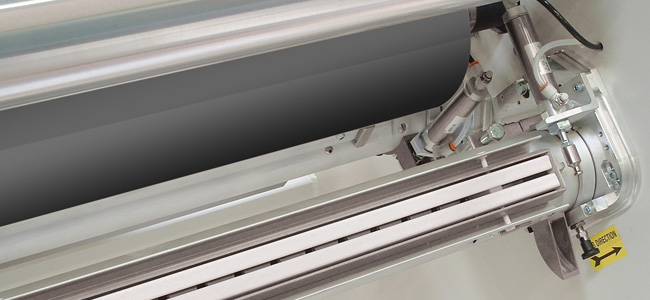

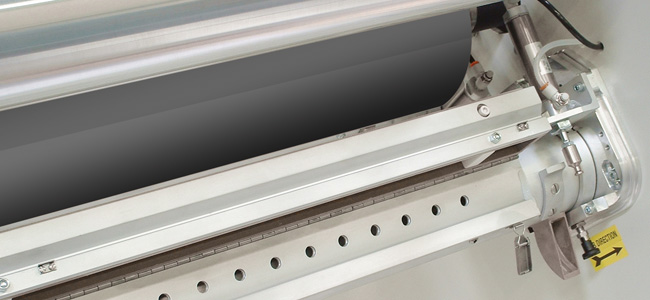

Electrode Assemblies

The most popular design for these applications incorporates our high powered ceramic electrodes and ground rolls capable of treating conductive and nonconductive films. The treater’s unique electrode assembly design removes ozone from the work area, pivots out of the way for splices and enables cleaning in place without the need to remove the electrode assembly.

Enercon systems are designed to operate in a maximum ambient temperature of 40°C (104°F) @ 80% relative humidity, non-condensing.

KEY FEATURES For Successful Printing, Coating & Laminating

-

Improve Surface Energy of All Types of Films

-

High-Definition Corona for High Value Films

-

Unique Electrode Assembly Design

-

Custom Configured for Your Application

CORONA TREATING POWER SUPPLIES

Our corona treaters are powered by Enercon’s world renowned Compak™ power supply technology. Their Universal design makes them compatible with any corona treater and application. With features like auto load matching, watt density control and proven industrial reliability Enercon power supplies are the leading choice of converters.

We’ll be happy to provide you with a proposal for your next project. Please contact us for a personal review of your application.

OPTIONAL EQUIPMENT Which may be recommended or specified:

-

Idler Rolls

-

Network Communication

-

Nip Rolls

-

Purged Station

-

Spare Electrodes

-

Spare Parts Kit

-

Spare Ground Rolls

-

Start-up Assistance

-

Station Guarding